Contractors create in-house training facilities to home-grow plumbing, HVAC techs

PHVAC contracting businesses create training programs and universities to combat labor shortage.

Every industry in the United States is currently feeling the constraints of the labor shortage. Employers continue to struggle to bring in new workers and keep existing ones. Job openings far outnumber individuals looking for work — in March, there were 11.5 million jobs to fill, and not enough workers to fill them, according to data from the U.S. Bureau of Labor Statistics Job Openings and Labor Turnover Summary.

The skilled trades are no stranger to these difficulties, having been dealing with the effects of the labor shortage for years now. However, some creative contractors have found a solution by creating paid in-house training programs to entice new employees to the plumbing and HVAC trades.

CroppMetcalfe Academy

Fairfax, Virginia-based CroppMetcalfe Services was ahead of its time when it established its apprenticeship program way back in 1988. The company actually has multiple training locations, one at its headquarters in Fairfax, and another in Beltsville, Maryland.

“We started out to be able to provide an attainable means for high school graduates to not only become educated but skilled within the trades,” says Gina Schmitt, manager of education for CroppMetcalfe Services. “We currently have plumbing and HVAC apprenticeship programs, and we’re going to be expanding to add an electrician program soon. Our main goal is to improve and grow the skilled trades workers and bridge that skills gap, and of course, generate that pipeline within CroppMetcalfe. Our apprentices graduate from our program as highly qualified technicians that represent our next generation of journeymen. It’s a pathway to a career for life.”

The four-year apprenticeship program is tuition-based but offers full reimbursement if the students stick with it for the entire four years.

“They will pay for the first two years themselves, then during year three, they get reimbursed for their first year of training, and year four offers reimbursement for their second year, and so on” Schmitt explains. “By the end of four years, they’ve had a free education with all their tuition fully reimbursed, plus they have had six years of experience with on-the-job training and receive their journeyman’s license.

“We have an earn and learn strategy,” she continues. “It combines on-the-job training during that four-year period with relational instruction. They get paid through a progressive wage scale we use.”

The Academy features a mixture of classroom, relational instruction, lab work and also recently incorporated virtual training.

“We’re starting to look at different options for integrating the latest 3D simulator technology,” Schmitt says. “We’ve used Oculus for some immersive technology that places the student in a virtual environment where they can interact and communicate as if they are in a real classroom. We started to look at this as a result of the last couple of years of COVID, which forced us to do a lot of things online. We were looking for ways to make it a bit more engaging and realistic. We currently have a few sets in our classroom in Beltsville. Eventually, we may have one for every student to use — some of them even have their own sets at home.”

Incorporating this technology has even helped draw more students to the program. “For high school graduates and people in their early 20s, they’re into all this technology — and it’s a better, more attentive learning environment. They’re out there working a full day in the heat, exposed to the elements, then they come to class and have to spend four hours in a classroom. We believe this 3D immersive learning will facilitate them learning the trades.”

CroppMetcalfe has partnered with the states of Virginia and Maryland for its apprenticeship programs, which help supply the curriculum for both programs. Schmitt says they have demonstrated some of the accredited 3D Interplay Learning programs for the states, which have started spreading the word on these alternate training opportunities.

TradeUp Academy

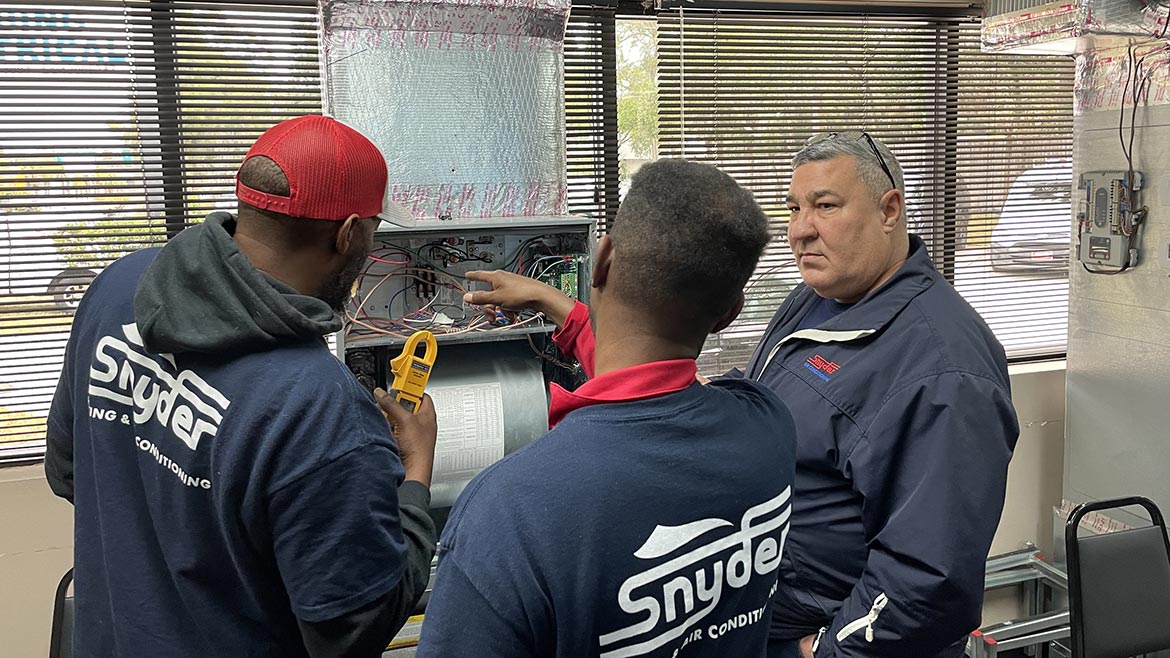

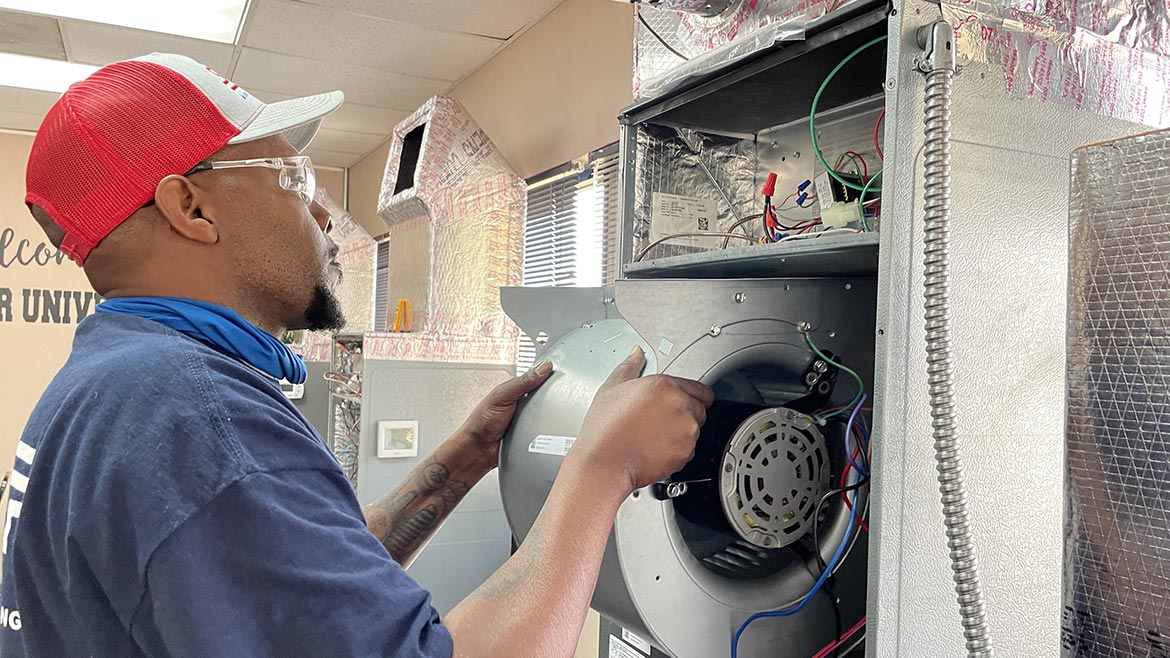

TradeUp Academy, launched this year by Jacksonville, Florida-based Snyder Air Conditioning, Plumbing & Electric, is a paid training and apprentice program that offers participants the opportunity to gain experience, learn new skills and support themselves financially while they study and receive on-the-job training.

“The big driver behind starting the TradeUp Academy is there is this skills gap in the marketplace right now, where we’re finding for whatever reason, enough people either don’t know about the great career opportunities that exist inside of home services, or they haven’t been exposed to it in a way that makes it feel attractive,” explains Shawn Vann, regional director of marketing for Snyder. “We decided to create this as a path to take people from never having thought about being in the trade to a certified technician. One of the things that we’ve found in doing that is now we don’t have to hire for experience and technical expertise, we can hire for the things that really matter and can’t be taught — such as personality, communication skills and just really genuine, nice folks. And we will teach them all of the technical stuff on top of that. It has allowed us to expand and diversify the pool of candidates that we have.”

Vann adds that Snyder is experiencing the same pressures as everybody else — it’s tough in the employer marketplace at the moment. “We thought why not create a place to grow these assets in-house versus having to rely solely on what the market delivers to us.”

Apprentices in the TradeUp Academy are considered full-time employees of Snyder and earn a competitive wage while receiving a minimum of 2,000 hours of firsthand technical training. The program consists of a mix of classroom training with online coursework before transitioning to ride-alongs with experienced Snyder technicians where they receive hands-on field training. Lastly, apprentices go out into the field in their own truck with support — a system in which the trainee can call in for assistance or request an experienced technician come to their job site for assistance.

Snyder spent months developing the year-long program, developing the coursework, searching for an instructor and finally, receiving approval from the Florida Department of Education. TradeUp Academy is also currently pending approval from the U.S. Department of Labor. A Registered Apprenticeship program ensures a quality education system with notable markers for advancement and employment.

“It has certainly been an arduous exercise, but I think that just shows our commitment to want to do it,” Vann says. “We wanted this to be a certified program through the state of Florida. So, what that means is, if we don’t create a wonderful environment for them to stay, they can take their credentials and leave and go wherever they want within the state of Florida.”

The first class began in January. There are currently five apprentices enrolled, who are now out in the field working on supervised maintenance calls. Snyder’s goal is to eventually do two to three classes a year with up to 10 students each. The company has a dedicated recruiter who searches for apprentices (and technicians at all experience levels).

Additionally, Vann notes the program will most likely expand to include apprenticeships for plumbing and electric — the other two services offered by Snyder. “The important thing for us was to create this program, do it well and test it for a few rotations. But I don’t think there are any limitations around us expanding into other trades.”

Carolina Cool Apprenticeship Program

Founded in 1985, Surfside Beach, South Carolina-based Carolina Cool boasts 100 fleet vehicles and more than 150 employees. The company’s training program began in 2010 as a basic “Ride and Decide” for local high school students or young people interested in the trades to participate on a job shadow or ride-along with experienced techs in the field. If the students expressed interest in the trades, Carolina Cool would encourage them to attend the local technical school, Horry-Georgetown Technical College in Myrtle Beach.

“Horry-Georgetown used to have all three trades — HVAC, plumbing and electrical, but they’ve dropped plumbing and electrical,” explains Tony Troiani, general manager, Carolina Cool. “They still have a pretty good HVAC program, so we still send a lot of guys through that. But it really forced us to create a new way for us to get more plumbers.”

So in 2018, Carolina Cool decided to team up with PHCC — National Association, tapping into the organization’s online training program to create a plumbing curriculum to train new employees. The coursework is designed to last four years; however, apprentices can finish it at their own pace — and some complete it early, Troiani notes.

“They also have to accumulate 8,000 hours working for us in the field — it’s 2,000 hours a year, then they leave the program as a certified plumber,” he explains. “We’ve just started getting our first apprenticeship graduates reaching 8,000 hours the last couple of months and earning their journeyman certificate.”

The company has certified its apprenticeship program through SC Works and Apprenticeship Carolina — two state-run agencies that provide support for apprentices by offering tools, rebates, waivers, gas reimbursement and even paying a portion of their wages while in the apprenticeship program.

“They help us by paying a portion of the apprentices’ wages for the first 800 hours, which is all negotiated by contract,” Troiani explains. “We’ve had a lot of support from our state government with this, too. There’s a lot of grant opportunities out there that they’ve tapped into. They put together a nice little package for us — it was a lot of work on our part, but it was a whole lot easier with the state help to get it done.”

Troiani notes that the apprenticeship program admits roughly eight to 12 apprenticeships per year — half are plumbing and the other half are HVAC. Though, not all of them finish, he adds. “Some realize it is not for them, and other times, we realize they are not a good fit for us.”

The company recruits apprentices through the local high schools, and Troiani sits on the advisory board for a local academy school that features a plumbing construction program.

“I meet with those students on a regular basis, and there’s another charter school that’s focused primarily on cars and automotive, but I recruit there a few times a year and offer them the opportunity to ride along with one of our technicians. Our county has not really allowed us to get out to recruit the past two years because of COVID-19, but we’ve had a couple of virtual opportunities to talk to high school kids.”

Troiani estimates that roughly 15% of the company’s existing workforce is apprentices it has hired and brought up. “These people wouldn’t have existed for us five years ago — we never would have had these employees. It’s been a fantastic way for us to internally grow our field staff because the number of technicians is limited. We just can’t find them locally. The techs in our area keep flip-flopping from one business to another, so we really need to train up younger people to grow our number of technicians here in South Carolina.”

He adds that PHCC is a great organization to team up with for in-house training.

“The content they provide is huge — we don’t have a way to provide the textbook and technical training ourselves,” he explains. “Having that as an option really opened the door for our technicians to provide the hands-on training without having to rely on all the little technical details. The apprentices that have gone through the PHCC online training get a really good, basic knowledge and understanding of the codes that are expected to be followed on job sites, especially with plumbing installations. That’s something that technicians should be talking about in the field with greener guys, but doesn’t always happen. It’s more of a, ‘We just do it this way.’ There’s no real in-depth explanations happening, so that’s what the textbook courses are for.”

Thornton & Grooms Academy

Farmington Hills, Michigan-based Thornton & Grooms also recently established an in-house training program for both plumbers and HVAC Technicians. Thornton & Grooms Academy launched October 2021 with a plumbing program, followed by the HVAC program this past January. The paid training program features five months of classroom, lab and field training within customers’ homes.

“We needed more people than we could recruit, and we also felt it was our duty to create new, young and complete talent within the industry,” says Matt Bergstrom, president of Thornton & Grooms. “We had apprentice programs in the past that were all field on-the-job training, and they took a long time and were not as successful as we would like.”

For the classroom and lab curriculum, Thornton & Grooms uses Nextech Academy, which is a comprehensive, online technical training program for HVAC, electrical and plumbing technicians offered by Nexstar Network. To date, Thornton & Grooms has graduated 22 plumbers and 11 HVAC technicians from its fast-track training program.

Bergstrom notes Thornton & Grooms advertised the program, and then looked for candidates who met the company’s culture and core values, and who were “hungry, humble and smart” — or willing to listen and learn as well as put in the hard work.

“Talent is getting hard to find, and it doesn’t do us contractors any good to just continue to trade talent around,” he says. “It also provided a new energy to our team with the youth and the newness to the trade. The training program allows each graduate to accelerate the learning of the trade quicker because they have a solid base to build upon. Lastly, it set them up well to pass their journeyman’s test in plumbing in 36 months, and to pass the core and specialty test to become NATE-certified.

“We want to train them to be great ambassadors of the trade, building upon its great traditions, and, at the same time, enhancing the integrity, honor and professionalism of the trades specifically in home service — because that is what we do day in and day out,” Bergstrom adds.