Rising interest and mortgage rates are putting pressure on home builders and engineers to deliver luxury features at lower costs and the choice of plumbing materials can factor into that. Photos courtesy of Lubrizol.

5 trends affecting residential plumbing systems

Design and material consideration is important for future-proofing plumbing systems.

Residential plumbing systems' basic design and composition don't change very often. However, various market forces and trends can influence the decisions plumbers and engineers make regarding those materials and designs. Here are five that should be considered in the coming year.

1. Luxury at lower costs

After declining during the second half of 2022 in response to rising interest rates, home prices have rebounded to near their July 2022 peak. However, according to the National Association of Realtors, those rate hikes increased the average cost of a monthly mortgage by 85% between January 2022 and August 2023.

That combination is putting pressure on home builders and engineers to deliver luxury features at lower costs and the choice of plumbing materials can help them accomplish that.

One example is luxury showers, which feature multiple body sprayers in addition to the showerhead. Pressures and flow within and between the various loops in a luxury shower system must be properly balanced and, whether using flexible or rigid piping, require equal lengths of pipe connected with elbows and tees. For the simplest designs, expect to use at least eight fittings per installation.

For plumbing systems that use insert fittings, this can add unexpected costs because insert fittings restrict flow and create larger pressure drops than the socket fittings used in copper and CPVC.

With so many fittings required, those losses are amplified in luxury showers. The only way to ensure sufficient water pressure is to upsize the loop piping and the branch line by one or two sizes, increasing the total cost of the feature.

Using a material immune to degradation from chlorinated drinking water allows velocities of 8-10 feet per second, eliminating the need for upsizing and allowing the full benefits of the system to be realized.

Using a material immune to degradation from chlorinated drinking water allows velocities of 8-10 feet per second, eliminating the need for upsizing and allowing the full benefits of the system to be realized.

With a material that uses socket fittings, upsizing may not be required. Exact pipe sizing will depend on street pressure, the location of the shower, the number of sprayers and the shower system manufacturer’s specifications. Still, CPVC will always enable smaller pipe sizes in these types of installs than a system that uses insert fittings. It is often possible to meet shower system pressure and flow requirements with 1/2-inch CPVC pipe within the shower assembly, allowing builders to deliver this coveted feature at a lower cost.

2. Optimizing multi-family designs

With multi-family development slowing somewhat compared to recent peaks, plumbing engineers have a chance to refine their designs and ensure they are meeting objectives.

One area of opportunity is in hot water recirculation systems. These systems can create conditions that accelerate degradation in plumbing materials susceptible to corrosion or degradation from chlorinated drinking water. As a result, some PEX material manufacturers and model codes limit water velocities in hot water recirculating systems using PEX to 2 feet per second.

That can impact flow rates across the system and may require upsizing the piping to compensate for the reduced velocities, negating the water-saving benefits of the system. Using a material immune to degradation from chlorinated drinking water allows velocities of 8-10 feet per second, eliminating the need for upsizing and allowing the full benefits of the system to be realized. CPVC is immune to chlorinated drinking water.

Remote or mini manifolds represent another opportunity for improved design. Mini manifolds are often installed in locations too far from the fixtures they support, requiring long branch lines that negate their benefits and add to project costs. Converting to manifold designs that actively minimize the length of branch lines can help realize the desired sustainability benefits.

FIGURE 1: A CPVC mini-manifold installed. This manifold design actively encourages short branch lines to optimize water savings.

3. Adapting to changing water treatment practices

As communities grow with new developments, water treatment facilities may increase the amount of disinfectants in the water supply to account for the longer distance water travels. In addition, there is a trend in municipal water treatment toward chlorine dioxide as an alternative to chlorine. According to public health professionals, chlorine dioxide is more effective than chlorine and chloramine disinfection against microorganisms and produces fewer disinfection byproducts of concern. Chlorine dioxide is also highly effective at killing viruses.

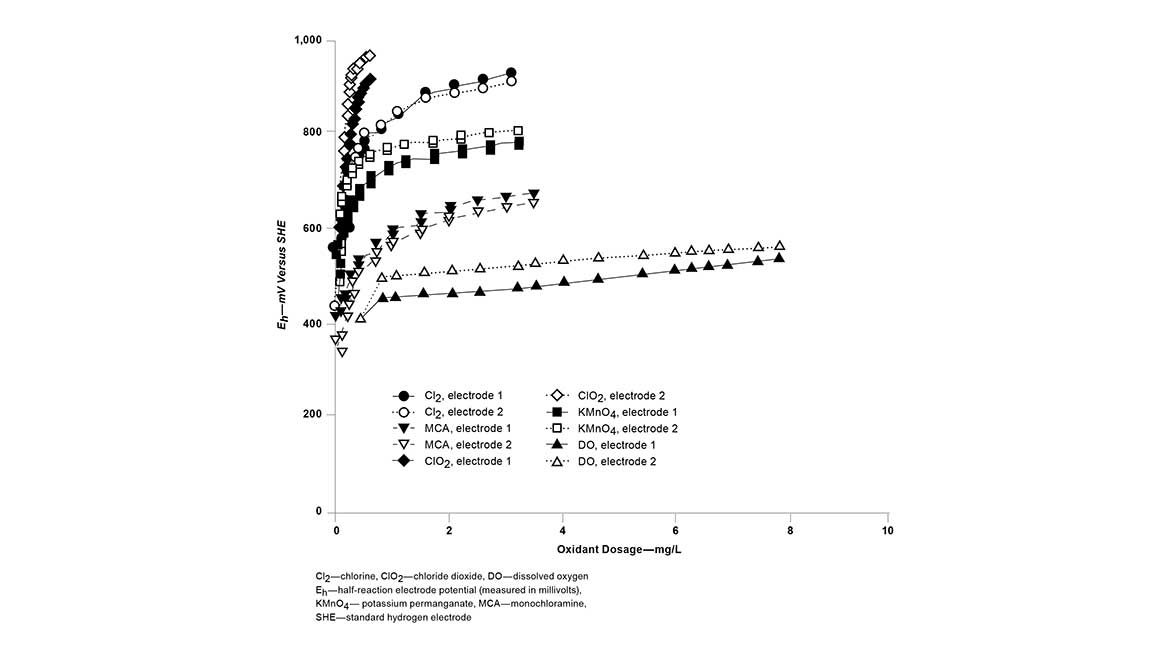

These changes in treatment practices can be hard on pipes that are vulnerable to degradation from chlorinated water. The Plastic Plumbing Institute’s Technical Note 53 identifies three factors that can accelerate chlorine degradation in PEX piping, including an Oxidative Reduction Potential (ORP) in the water flowing through the pipes above 825 mV.

As water treatment practices continue to evolve, choosing plumbing systems that are inherently immune to chlorinated drinking water becomes more critical than ever.

Disinfectants are just one of the factors that contribute to ORP in municipal water systems — dissolved oxygen, metal ions and salts also increase ORP — and the use of chlorine dioxide (CIO2) can drive ORP above the threshold by itself. As water treatment practices continue to evolve, choosing plumbing systems that are inherently immune to chlorinated drinking water becomes more critical than ever.

FIGURE 2: Chlorine dioxide is proving to be an effective disinfectant but poses risks to plumbing materials vulnerable to chlorine degradation. Source: “Measuring the oxidation-reduction potential of important oxidants in drinking water;” A. Copeland, D. Lytle; 2014

4. Increasing focus on material sustainability

Embodied Energy is growing in importance as a metric for builders and engineers seeking materials that minimize greenhouse gas emissions in their manufacture and transportation.

Plastic plumbing materials will generally have a lower embodied energy than copper, and CPVC has a lower embodied energy than other plastic plumbing materials. According to data in the National Institute of Standards and Technology (NIST) Building for Environmental and Economic Sustainability (BEES) database, a CPVC plumbing system emits nearly 1 ton less carbon into the atmosphere than a PEX plumbing system over the life of a small house — the equivalent of 105 gallons of gasoline.

A lifecycle assessment can provide an objective, third-party and quantitative analysis of a system’s cradle-to-grave environmental impact. Certifications, such as those offered by the Home Innovation Labs National Green Building Standard (NGBS), can also be helpful in evaluating material sustainability.

5. Up-skilling the labor force

Consistent demand despite challenging economic conditions is driving an increase in skilled labor development as companies recognize the risk of being overly dependent on unskilled labor that limits their ability to take advantage of lower-cost and higher-performing plumbing systems. As they increase their focus on up-skilling, they are finding resources available through plumbing system manufacturers that enable flexible and time-efficient skills development. Some manufacturers also provide on-site project support to aid contractors in transitioning to new materials.

Future-proof plumbing system design

As market conditions and water treatment processes continue to evolve, some materials and designs will prove better able to handle change and deliver reliable and cost-effective performance. Materials that are inherently immune to chlorinated drinking water and that don’t restrict water flow are more adaptable to changing conditions and represent the best choice for future-proofing plumbing system design.